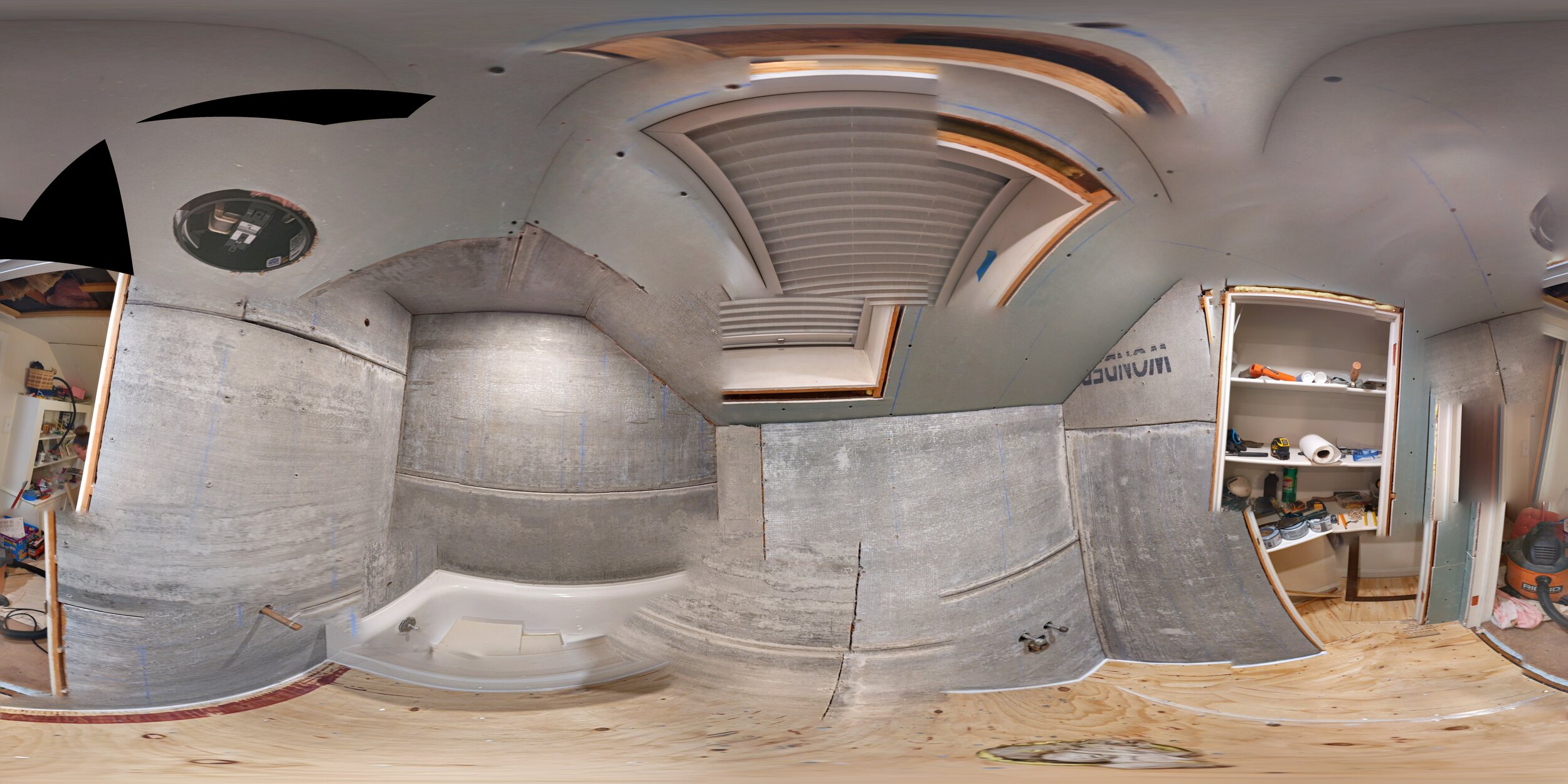

So the walls and ceiling are done… just gotta get something on this floor. After the hexagon tiles and So. Much. Cutting., these squares should be a breeze!

…Only, I wanted them offset AND at an angle. Did I mention my husband is long-suffering with my ideas? Once again, something that could have been fine and simple was instead complicated—but, I think, a better end result.

NOTE: Skip back if you want to see an overview (including “the before”) or previous steps we’ve already completed, or skip ahead if you’re looking for a different step in the process.

STEP 11: Tiling the floor

Tiling the floor doesn’t end up functionally being a great deal different than the walls. Make sure you read the labels to be sure your tile selection is made for traffic. We used a 12” square in light grey.

LAY OUT YOUR PATTERN

Pick your starting place — in our case, by the tub. We knew it was critical to line everything up before we started cutting or placing in order to make sure we didn’t end up with any small tile nubbins. My tiles are 12” and offset 30 degrees and 1.75”.

We used the same hole drill from the wall tile to cut out the space for the toilet, then a regular tile saw for all the edges. We stuck with our trusty tile spacers to ensure the lines were perfect.

You want to lay a level on EACH piece because your feet are more perceptive than you think, and you’ll feel it if you step between tiles that are a smidge higher or lower. Also, be careful walking or leaning/pressing too hard or you’ll crack the tile before the thinset dries.

GROUT

For the grout, we used the same as the walls to create some uniformity, but obviously the sky is the limit for what you like. The nice part about this was the line between the floor and the wall is just the grout color — it’s such a beautiful clean line rather than adding a quarter-round piece or trying to have lines of one color pouring into a line of another.